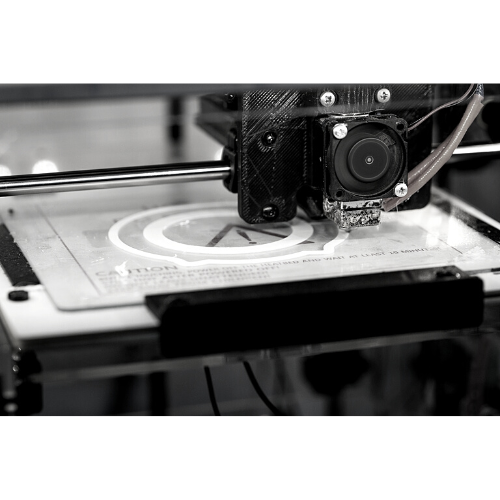

3D printing can be used to create objects with smooth or textured surfaces, depending on the specific printing technology and material being used.

Can 3D printing be used to create objects with smooth or textured surfaces?

Fused filament fabrication (FFF) and selective laser sintering (SLS) are two common 3D printing technologies that can produce objects with smooth surfaces. These technologies work by building up layers of material to create the final object, and the smoothness of the surface can be controlled by adjusting the layer height and print resolution.

Stereolithography (SLA) is another 3D printing technology that can produce objects with smooth surfaces. This technology works by using a laser to cure a liquid resin into a solid object, and the smoothness of the surface can be controlled by adjusting the print resolution.

In contrast, some 3D printing technologies, such as material extrusion and digital light processing (DLP), can be used to create objects with textured surfaces. These technologies work by building up layers of material and using a specialized print head or light source to create a textured finish on the surface of the object.

Overall, the smoothness or texture of the surface of a 3D printed object can be controlled by choosing the appropriate printing technology and adjusting the print resolution and other parameters as needed.

| Aspect | Smooth Surfaces | Textured Surfaces |

|---|---|---|

| Print Settings | Higher resolution, slower print speed | Lower resolution, faster print speed |

| Post-processing | Likely requires sanding or other treatments | Minimal to no post-processing required |

| Material Used | Any type, but smooth results best with ABS, PLA | Any type, but textures often more pronounced with ABS, PETG |

| Aesthetic | Gives a clean, polished look | Can provide unique tactile feel and visual interest |

| Print Time | Longer due to high resolution | Shorter due to lower resolution |

| Difficulty | Requires more precision, may be more challenging | Easier due to less need for precision |

| Applications | Ideal for professional, detailed models | Ideal for objects where grip or decorative texture is desired |

| Design Consideration | Must account for post-processing | Design incorporates desired texture |

I am highly passionate about 3D printing and find great joy in writing about it. The ability to bring a digital model to life in three dimensions has captivated me since I first learned about this technology. I am constantly learning about the latest advances and trends in 3D printing, and I enjoy sharing my insights and experiences with others. Writing about 3D printing allows me to share my enthusiasm for this innovative field and assist others in gaining a deeper understanding of its principles.

Examples

Here are a few examples of products that can be produced with smooth or textured surfaces using 3D printing:

Smooth surfaces:

– Jewelry: 3D printing technologies such as SLA and SLS can be used to create jewelry with very smooth surfaces, as these technologies are capable of creating very fine details and smooth finishes.

– Dental models: 3D printing technologies such as FFF and SLA can be used to create dental models with smooth surfaces, as these technologies are able to create detailed and accurate representations of the teeth and gums.

– Medical models: 3D printing technologies such as SLS and SLA can be used to create medical models with smooth surfaces, as these technologies are able to create detailed and accurate representations of the human body.

Textured surfaces:

– Footwear: 3D printing technologies such as material extrusion and DLP can be used to create footwear with textured surfaces, as these technologies are able to create a variety of different textures on the surface of the object.

– Architectural models: 3D printing technologies such as FFF and SLS can be used to create architectural models with textured surfaces, as these technologies are able to create a variety of different textures on the surface of the object.

– Consumer products: 3D printing technologies such as material extrusion and DLP can be used to create consumer products with textured surfaces, such as phone cases and home decor items.

Overall, 3D printing can be used to create a wide range of products with smooth or textured surfaces, depending on the specific technology and materials used. By choosing the appropriate technology and adjusting the print settings as needed, it is possible to create products with a variety of different surface finishes.