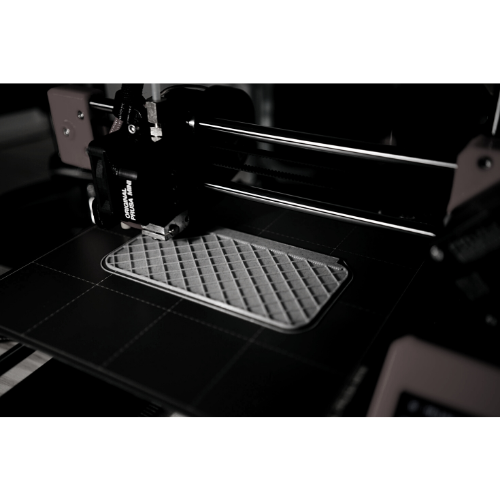

The speed at which a 3D printer can print depends on a number of factors, including the type of printer being used, the material being printed with, and the size and complexity of the object being printed.

Metrics

There are several ways to measure the speed of 3D printing, and the appropriate measure often depends on the type of printer and the specific aspect of the process you’re interested in. Here are a few common units of measure:

Millimeters per second (mm/s): this is the most common measurement of 3D print speed, especially for Fused Deposition Modeling (FDM) printers. It refers to the speed at which the print head moves while it’s printing.

Seconds per layer: for resin-based printers like Stereolithography (SLA) or Digital Light Processing (DLP) printers, it’s common to measure the speed in terms of the time it takes to expose each layer.

Cubic millimeters per hour (mm³/hr) or cubic inches per hour (in³/hr): this is a measurement of the volume of material that can be printed in a given amount of time. It can be a useful measure for comparing the overall throughput of different printers or print settings.

Objects per hour: in industrial settings, it might be more useful to measure the speed in terms of the number of complete objects that can be printed in a given amount of time.

What are the 3D printing speed ranges?

In general, 3D printers can be grouped into three categories based on their printing speed: slow, medium, and fast. Here are some rough estimates for the speed ranges of these categories:

Slow: <50 mm/s. These printers may be suitable for printing very detailed objects, but may be too slow for larger or more complex prints.

Medium: 50 mm/s – 200 mm/s. These printers are suitable for a wide range of applications, including printing both small and large objects with moderate levels of detail.

Fast: >200 mm/s. These printers are capable of printing very quickly, but may sacrifice some detail in order to do so.

Keep in mind that these are just rough estimates and the actual print speed can vary significantly based on the specific printer and print settings being used.

3D printing is my passion and I enjoy writing about it. Ever since I discovered 3D printing, I have been fascinated by the opportunity to create three-dimensional objects from a digital model. I enjoy studying the latest technologies and trends in 3D printing, and I enjoy sharing my knowledge and experience with others. Writing about 3D printing is a way for me to express my passion for this technology and to help others better understand its principles and applications.

Technical details

The speed in 3D printing is multifaceted and depends on numerous factors such as the printer technology, material used, layer height, part geometry, and infill density.

| Factor | Description |

|---|---|

| Printer Technology | Different types of 3D printers (FDM, SLA, DLP, SLS, MJ, MJF, BJ) have varying printing mechanisms, which impacts their print speeds. |

| Layer Height | Layer height influences the print speed. Higher layer height means fewer layers, thus faster print times, but at the expense of resolution and detail. |

| Print Quality | Higher quality prints often require slower print speeds to ensure precision and detail. |

| Print Material | Different materials may require different print speeds. For instance, some materials might need slower speeds to ensure proper adhesion between layers. |

| Printer Calibration | Properly calibrated printers can work at their optimal speeds. Misalignment or improper calibration can cause print errors, requiring slower speeds. |

| Part Geometry | The complexity of the part being printed can affect print speed. Complex parts with many overhangs, bridges, or intricate details may require slower speeds. |

| Infill Percentage | A higher infill percentage will increase the print time as the printer has to deposit more material. |

| Printer Hardware | The specific hardware of the printer, including the motors, belts, and print head, can impact the speed. Higher-end hardware can often operate at higher speeds. |

| Slicer Settings | The settings chosen in the slicer software can greatly affect the print speed. These settings include layer height, print quality, print temperature, and others. |

Overall, the print speed of a 3D printer can vary significantly based on these and other factors. It’s generally a good idea to use a slicing software to estimate the print time and adjust the print speed accordingly before starting a print.