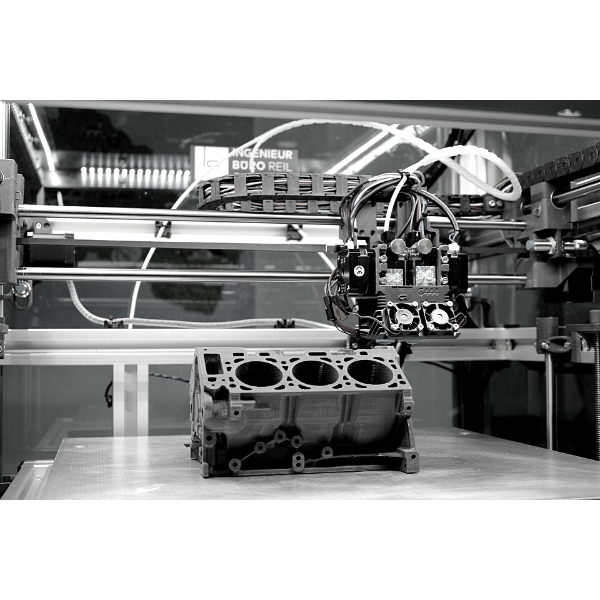

3D printing is a rapidly evolving technology that allows users to create physical objects from digital models. In order to produce high quality 3D prints, it is important to have a solid understanding of the printing process and use appropriate software and techniques. In this list, we will go over some advanced programming recommendations for 3D printing, including the use of 3D modeling software, slicer software, and printer control software, as well as techniques for optimizing print quality and troubleshooting common issues.

By following these recommendations, you can improve your 3D printing skills and produce professional-grade prints.

Use a 3D modeling software

Use a 3D modeling software to design your 3D model, some popular options include AutoCAD, Blender, and Fusion 360.

- 3D modeling software allows you to create a digital representation of the object you want to print.

- There are many different 3D modeling software options available, ranging from simple, free tools to professional-grade programs.

- Some popular 3D modeling software options include AutoCAD, Blender, and Fusion 360.

- It is important to choose a software that is suitable for your needs and skill level, as well as compatible with your printer and slicer software.

Export your model

Export your model as a .STL or .OBJ file, which are the most common file formats for 3D printing.

- Once you have designed your 3D model, you will need to export it as a file that can be read by your slicer software.

- The .STL (STereoLithography) and .OBJ (Object) file formats are the most commonly used file formats for 3D printing.

- These file formats contain a 3D mesh of the model, with the .STL format being more widely supported by slicer software.

- Make sure to save your file in the correct format and with a clear, descriptive file name.

Use a slicer

Use a slicer software to convert the 3D model into printer-readable G-code. Some popular slicer software options include Cura, Slic3r, and Simplify3D. In the slicer software, set the appropriate print settings for your printer, such as layer height, infill density, and print speed.

- A slicer software is used to convert the 3D model into a set of instructions, called G-code, that can be understood and executed by your 3D printer.

- The slicer software takes the 3D model and “slices” it into layers, which are then printed one by one by the printer.

- Some popular slicer software options include Cura, Slic3r, and Simplify3D.

- It is important to choose a slicer software that is compatible with your printer and allows you to customize print settings, such as layer height, infill density, and print speed.

Test and calibrate the 3D printer

Make sure to adequately test and calibrate your printer before starting a print, as this can greatly affect the quality of the finished product.

- Before starting a print, it is important to ensure that your printer is properly calibrated and functioning correctly.

- This includes checking the bed level, nozzle height, and extruder tension, as well as performing any necessary maintenance on the printer.

- Proper calibration and maintenance will help to ensure that the print comes out as intended and reduces the risk of issues occurring during the printing process.

Use a control software

Consider using a printer control software, such as OctoPrint, to remotely monitor and control your printer.

- Printer control software allows you to remotely monitor and control your printer from a computer or smartphone.

- This can be particularly useful if you are running multiple prints or if you are not physically present to oversee the printing process.

- OctoPrint is a popular open-source printer control software that allows you to upload and slice models, start and stop prints, and adjust printer settings from a web interface.

Debug

Use error-checking and debugging techniques, such as adding support structures or using a filament runout sensor, to troubleshoot any issues that may arise during the printing process.

- Despite your best efforts, issues may still arise during the printing process.

- To troubleshoot these issues, it can be helpful to use error-checking and debugging techniques, such as adding support structures to prevent warping or using a filament runout sensor to detect when the filament has run out.

- It is also important to regularly check the printer and clear any blockages or jams that may occur.

Advanced techniques

Consider using advanced techniques, such as variable layer height or adaptive slicing, to optimize the quality and efficiency of your prints.

- As you become more advanced in your 3D printing skills, you may want to consider using advanced techniques to further optimize the quality and efficiency of your prints.

- One such technique is variable layer height, which allows you to print with different layer heights in different parts of the model. This can result in a higher resolution print, as the printer can focus on areas of the model that require more detail.

- Another technique is adaptive slicing, which adjusts the slicing parameters based on the specific features of the model. This can result in a more efficient print, as the slicer software can use less material and shorter print times in areas that do not require as much detail.

- These techniques can be complex and may require specialized software or hardware, so it is important to carefully research and understand them before attempting to use them.

Overall, it’s important to stay up to date with best practices and new developments in the field of 3D printing, as the technology is constantly evolving.