ELEGOO is a brand in the field of 3D printing, particularly popular for its resin 3D printers. These printers, often used by hobbyists and professionals, offer high print quality at competitive prices. Let’s take some time to look together at the different products offered by ELEGOO and carefully browse the catalog so that you can evaluate the various options and make an informed choice.

Elegoo is a company that manufactures a range of 3D printers, particularly resin 3D printer models.

Over thepast few years, access to 3D printing has become increasingly widespread. In practice, more and more manufacturers have begun to offer equipment at lower costs, making the technology more affordable for a global audience. Among these manufacturers offering desktop machines at more competitive prices is the Chinese company ELEGOO.

In 2015, Chris Hong founded Elegoo in China’s Silicon Valley, Shenzhen, with the goal of providing makers around the world with truly practical electronic and structural toolkits that students, enthusiasts, and veteran geeks may find necessary in their phases.

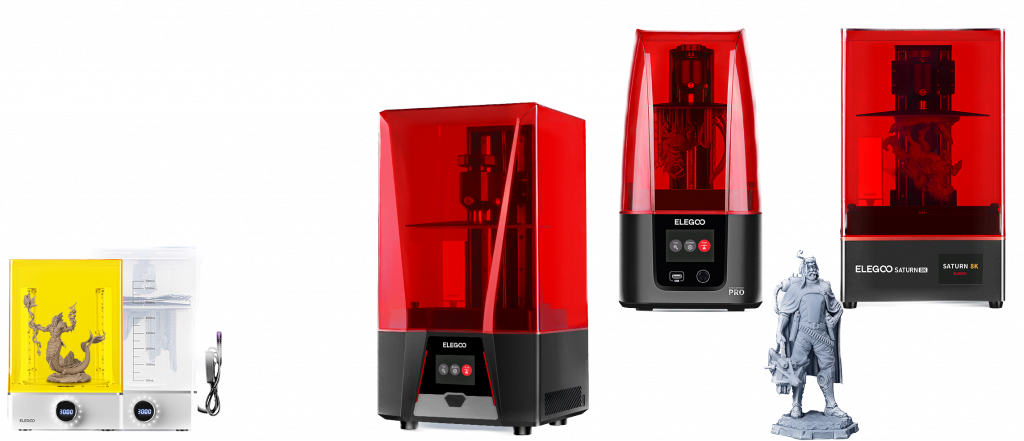

The ELEGOO Catalog

ELEGOO’s 3D printers are known for their reliability and ease of use. They are especially popular with 3D printing enthusiasts, who use them to create objects of all kinds, from car models to children’s toys. ELEGOO’s 3D printers come in a wide range of models, ranging from the simplest and most affordable to the most advanced and professional. Among the most popular are the Mars 3D printer and the Saturn 3D printer.

Neptune Series

Neptune 4 Pro: This flagship model of the Neptune series is designed for professionals. It boasts exceptional print quality, a larger build volume, and advanced features such as dual extruders and AI-enhanced error detection.

Neptune 4: A versatile, high-quality printer with an improved design for easy assembly and maintenance. Ideal for hobbyists, designers and small businesses.

Neptune 3 Max: equipped with advanced features such as auto-levelling, filament detection and recovery in case of power loss. It also boasts a significantly higher print volume than its predecessor.

Neptune 3 Plus: a perfect blend of performance and convenience, it offers reliable print quality and user-friendly features such as a touchscreen interface and quiet operation.

Neptune 3 Pro: geared toward prosumers, it offers advanced features such as direct-drive extrusion and improved thermal management for superior precision printing.

Neptune 3: This entry-level model offers reliable 3D printing capabilities for beginners and hobbyists, with an emphasis on user-friendly operation and affordable price.

Jupiter Series

Jupiter 6K: an industrial-grade printer renowned for its large print volume, high-speed operation and exceptional resolution. Ideal for commercial and large-scale production applications.

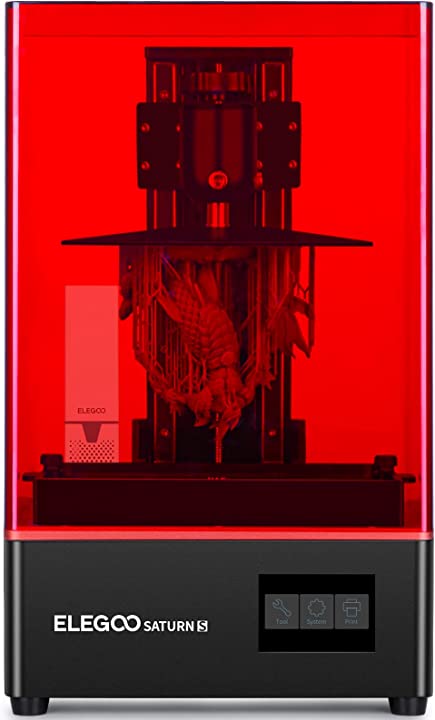

Saturn Series

Saturn 3 Ultra 12K: This is the flagship model offering colossal build volume, ultra-high resolution of 12K, and features such as multi-material printing and advanced temperature control.

Saturn 3 12K: Similar to the Ultra model but with a smaller build volume, it still maintains the impressive 12K resolution, making it ideal for intricate and detailed projects.

Saturn 2 8K: This printer offers a substantial 8K resolution, making it ideal for professionals who need fine detail in their prints.

Saturn 8K: A more affordable option, it offers high-resolution prints without the additional advanced features of the numbered models.

Saturn S 4K: This entry-level printer in the Saturn series offers 4K resolution printing, excellent for beginners looking for a quality start in 3D printing.

Mars Series

Mars 4 Ultra 9K: This top-level printer in the Mars series boasts 9K resolution and a wide range of features such as quiet operation, improved speed, and advanced temperature control.

Mars 4 9K: This model retains the Ultra’s impressive 9K resolution but at a more affordable price, making it perfect for enthusiasts who prioritize print quality.

Mars 4 Max 6K: a mid-range model that offers a balance of cost, functionality and a respectable 6K resolution.

Mars 4 DLP: this is a Digital Light Processing printer designed for exceptional detail and smoothness, making it ideal for jewelry, dentistry and other precise applications.

Mars 3 Pro 4K: offers professional-grade features such as improved speed, stability and 4K resolution.

Mars3 4K: a more affordable option in the Mars series with 4K resolution, perfect for beginners and enthusiasts.

Mars 2 Pro 2K: This entry-level model offers a respectable 2K resolution, making it a great choice for beginners who are starting out with 3D printing.

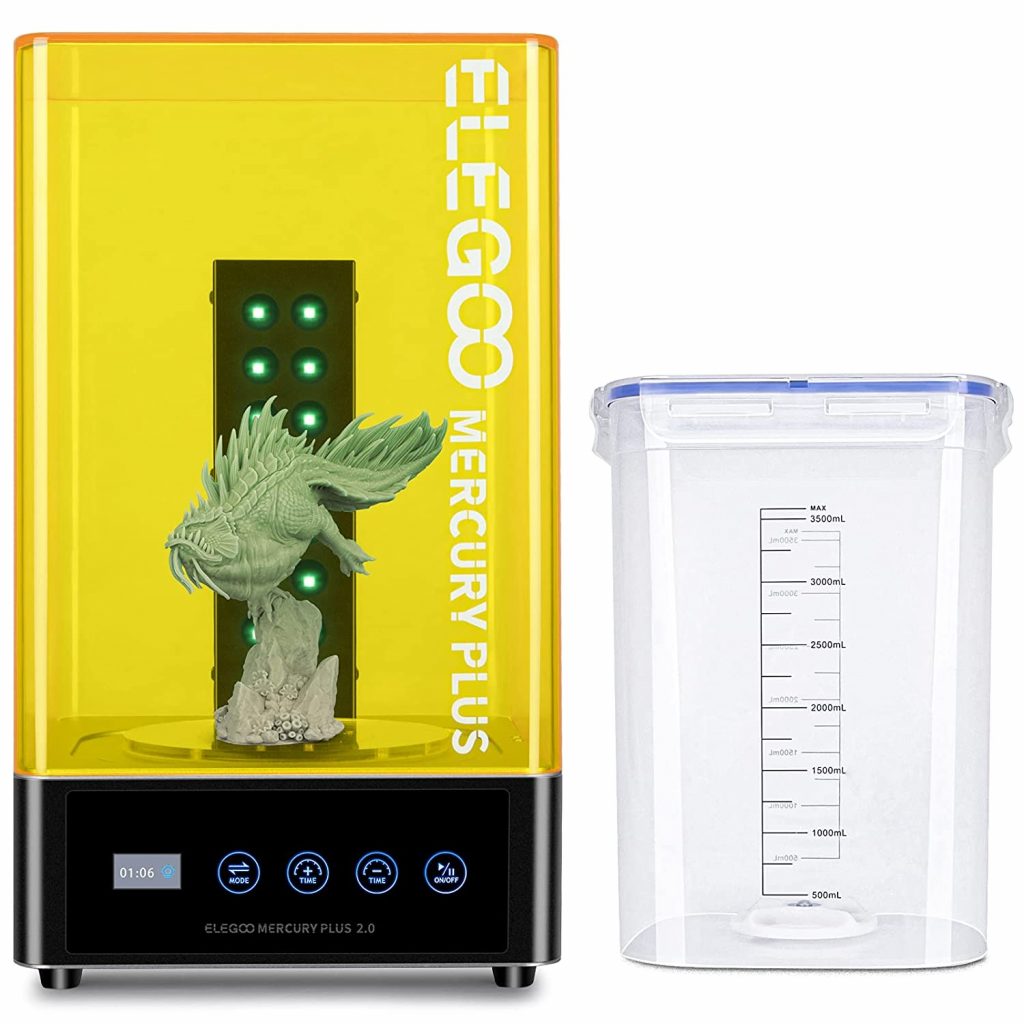

Mercury Series

Mercury XS Bundle: an all-in-one package designed for beginners, with a compact printer, user-friendly operation and all necessary accessories included.

MercuryX Bundle: a slightly larger package than the XS, offering a larger build volume and the same ease of use.

Mercury Plus V2.0: an updated version of the original Mercury Plus, features improved performance, quieter operation and a refined user interface.

MercuryPlus V1.0: this entry-level model is perfect for those new to 3D printing, offering easy assembly, user-friendly operation, and reliable print quality.

Resin for 3D Printing

Elegoo 3D printers are resin printers. They use a process known as photopolymerization, in which an LCD projects light onto a photosensitive resin that hardens to form the layers of the printed object. They do not use filament as in FDM (Fused Deposition Modeling) 3D printers.

Although Elegoo 3D printers are optimized for use with Elegoo resin, they can be used with any type of LCD compatible resin.

MSLA, DLP and LCD 3D printers

3D printers use MSLA, DLP and LCD printing technologies. These technologies are based on the use of photosensitive resin. Let’s find out about them together.

MSLA 3D printers

Technology: MSLA printers use masked stereolithography technology. They use an LCD panel to create a “mask” of UV light that is then projected onto the photosensitive resin. This mask determines which parts of the resin will be cured to form the layer of the printed object.

Speed: MSLA printers can print entire layers of an object at once, which can make them faster than other resin-based 3D printing techniques such as DLP (Digital Light Processing).

Quality: MSLA printers can produce high-resolution prints, although the final quality may depend on the specific type of printer and settings used.

Materials: these printers use photosensitive resin as the printing material.

LCD 3D printers

Technology: LCD 3D printers use an LCD panel to project UV light onto the photosensitive resin. This is very similar to MSLA technology, so much so that sometimes the two terms are used interchangeably. The main difference is that LCD printers use a more uniform light source behind the entire screen, while MSLA printers can have multiple light sources placed strategically.

Speed: Like MSLA printers, LCD printers can print entire layers of an object at once, which can help speed up the printing process compared to other resin 3D printing techniques.

Quality: LCD printers can produce high-quality prints with good resolution, although the final quality may depend on the specific printer model and settings used.

Materials: LCD printers use photosensitive resin as the printing material.

DLP 3D printers

Technology: DLP printers use digital light processing technology. This process involves a UV light source that is projected onto a DLP chip. This chip, composed of millions of micro-mirrors, directs the light to create the desired image (or pattern). This image is then projected onto the photosensitive resin, causing it to cure (or harden) to form a layer of the printed object.

Speed: DLP printers, such as LCD and MSLA printers, can print entire layers of an object at once. However, the printing speed depends largely on the power of the UV light source and the time it takes to fully cure the resin.

Quality: DLP printers are known for their ability to produce high-quality prints with very fine resolution, making them ideal for detailed applications such as jewelry or dentistry.

Materials: DLP printers use photosensitive resin as the printing material. There are various types of resins available on the market, including standard resins, flexible resins, casting resins and others, depending on the specific needs of the user.

Differences between MSLA, LCD and DLP

Resin 3D printing is based on several technologies, including MSLA (Masked Stereolithography), DLP (Digital Light Processing) and LCD. Each of these technologies has its own strengths and challenges.

MSLA uses an LCD panel to create a “mask” of UV light, which is then projected onto the photosensitive resin. The mask determines which parts of the resin will be cured to form the layer of the printed object. The main strength of this technology is its speed: it can print entire layers of an object at once, making it faster than many other resin 3D printing techniques. However, the quality of MSLA prints can vary depending on the type of printer and settings used.

DLP printers, on the other hand, use digital light processing technology. They project a UV light source onto a DLP chip composed of millions of micro-mirrors. These micro-mirrors direct the light to create the desired image that is projected onto the resin, causing it to cure. The main advantage of DLP printers is their ability to produce high-quality prints with very fine resolution, making them ideal for detailed applications. However, print speed can be slower than MSLA or LCD techniques because of the need for a longer exposure time to fully cure the resin.

Finally, LCD printers use an LCD panel to project UV light onto the photosensitive resin. This technology is very similar to MSLA, with the main difference being that LCD printers use a more uniform light source behind the entire screen. Like MSLA printers, LCD printers can print entire layers of an object at a time, speeding up the printing process compared to the DLP technique. The resolution and quality of prints, however, may vary depending on the printer model and settings used.

ELEGOO models on the market

Some of the most popular models of Elegoo 3D printers include the Elegoo Mars, the Elegoo Mars 2, the Elegoo Mars Pro, and the Elegoo Saturn.

Elegoo Mercury XS Bundle

| Features | Description |

|---|---|

| Full 360-degree illumination | Post-curing is based on 2 L-shaped light bars (each with 14 integrated UV LEDs) and 4 additional UV LEDs located under the turntable. The combination of the 360-degree automatic turntable and the handheld UV lamp ensures that all corners and interiors of 3D prints are cured, allowing curing without shadow spots. |

| Combined Cleaning and Curing Functionality | The ELEGOO Mercury XS bundle includes a cleaning station and a post-curing station, used to remove uncured resin from 3D prints and improve the quality of prints, making post-processing easy and efficient. |

| Large Cleaning Capacity | Equipped with an airtight water tank with a generous capacity of 7000 ml, it allows large models or groups of parts to be cleaned at once, saving time and increasing productivity. |

| Simple and Direct Operation | A single button makes it easy to turn on the device and set the time for cleaning or curing. The UV cover repels 99.9 and UV rays, providing eye protection during post-curing. |

| Extended Compatibility | Compatible not only with the ELEGOO Saturn and Mars 3 3D printers, but also with other LCD/DLP/SLA resin 3D printers with similar build sizes available in the market, facilitating and efficient post-processing of 3D resin prints. |

ELEGOO Saturn 2

| Features | Description |

|---|---|

| 10-inch 8K monochrome LCD screen | The ELEGOO Saturn 2 uses a 10-inch 8K monochrome LCD screen with an HD resolution of 7680×4320 and an outstanding XY accuracy of 28.5 microns. This enables the creation of highly detailed 3D models with curing times between 1-3 seconds per layer. Protection is provided by 9H scratch-resistant glass that also improves light transmission. |

| 43% more print volume | With a build volume of 219x123x250 mm / 8.62×4.84×9.84 inches and its 10-inch monochrome LCD screen, the printer enables a significant increase in curing efficiency and prototype size. One larger model or more small models can be printed at the same time. |

| Light source with Fresnel collimation | This light source uses Fresnel collimation with 48 highly integrated UV LEDs, a free-form COB lens, and a Fresnel lens in the FCL system. This produces a homogeneous 405 nm light beam with 92 percent light uniformity, ensuring superior printing accuracy and smoother surface finish. |

| Reliability in printing | The Z-axis design includes dual linear guides and non-slip hexagonal leveling screws to ensure precise and stable movements. The sandblasted build plate ensures high adhesion, while the PFA release coating facilitates pattern removal and decreases release tension. |

| Odor-free printing | The air filtration unit, equipped with an activated carbon filter, reduces most resin odors, ensuring a fresh, odor-free printing environment. Dual heat conduction copper heat ducts offer faster heat transfer and superior cooling efficiency, extending the life of 3D printers. |

With a large build volume of 192 * 120 * 200 mm, Saturn is ideal for larger 3D printing projects. It uses mono 4K LCD printing technology to offer accurate details and shorter print times.

ELEGOO Mars 3 Pro

| Features | Description |

|---|---|

| Monochrome 4K LCD Display | A 6.6-inch 4K monochrome LCD display with interchangeable tempered glass cover, featuring 9H-grade scratch resistance for high light transmission. The resolution reaches 4098 x 2560, ensuring accurate reproduction of model details. |

| Advanced COB Light Source | Implements an improved free surface COB lens composed of 36 strongly integrated UV LEDs. It cooperates with the Fresnel lens to produce a uniform light beam at 405 nm wavelength, promoting a smoother printing surface and superior print quality. |

| Large Print Capacity | Offers a substantial build volume of 143.43 × 89.6 × 175 mm (5.647 × 3.52 × 6.8 in.), enabling large or multiple smaller models to be printed simultaneously, optimizing time and productivity. |

| Reliable Structure | Features non-slip hexagonal leveling screws and a construction plate with sandblasted oxide surface for improved adhesion and printing stability. PFA release insert reduces release tension, increasing the probability of printing success. |

| Optimized Printing Experience | Equipped with an air purifier equipped with an activated carbon filter to absorb and filter resin odor and pungent fumes. Includes copper heat pipes and a performance cooling fan for efficient heat transfer and cooling, extending the life of the 3D printer. |

This single LCD 3D printer offers significantly better printing speed than previous models. With a build volume of 129 * 80 * 160 mm, it allows for decent-sized models. Its high resolution and excellent accuracy make it perfect for printing miniatures and fine details.

How to approach 3D printing?

I. Understand what 3D printing is: 3D printing, or additive manufacturing, is a process that creates three-dimensional objects from a digital file. It uses successive layers of material to build the object, which can be created from a variety of materials, from metals to polymers.

II. Choosing the right 3D printer for you: choosing a 3D printer depends on several factors, including budget, experience, intended use, and the time and effort you are willing to devote. There are different types of 3D printers, such as:

- FDM (Fused Deposition Modeling) 3D printers: this is the most common and affordable type of 3D printer. It uses a plastic filament that is heated and deposited layer by layer.

- SLA (Stereolithography) and DLP (Digital Light Processing) 3D printers: these types of printers use a photosensitive resin that is hardened by a light source, usually a laser or UV projector, to create objects with high resolution and detail.

III. Know the 3D software: To create a 3D printable object, you will need a 3D model. This can be created using 3D modeling software or downloaded from specialized websites. The 3D model file must then be “fated” into layers using slicing software, which translates the model into instructions understandable by the 3D printer.

IV. Learning to print: 3D printing requires a certain learning curve. You may need to experiment with various parameters such as print temperature, print speed, layer height and fill settings to get the best results.

V. Maintenance and safety: like any other device, 3D printers require regular maintenance to ensure long life. In addition, it is important to follow safety guidelines, such as using a well-ventilated area when printing and wearing eye and hand protection when handling the printer or materials.

VI. Explore the possibilities: once you become familiar with the fundamentals of 3D printing, the sky is the limit! You can use 3D printing for everything from product prototypes, to custom parts, to creating unique works of art.

3D Printing in Safety

| Precautions | Description |

|---|---|

| 1. Environment | Avoid placing the printer in unstable or vibration-prone environments, as this may adversely affect print quality. |

| 2. Thermal safety | Avoid touching the print head and print bed when the printer is in operation to prevent high temperature burns and personal injury. |

| 3. Head Cleaning | After printing, use residual heat from the head and appropriate tools to clean any filament residue. Avoid direct contact with the head to prevent burns during cleaning. |

| 4. Maintenance | Perform printer maintenance regularly. When the printer is turned off, use a dry cloth to remove dust and any sticky residue from the printer body. |

| 5. Moving parts | Be careful around 3D printers as they contain high-speed moving parts. Be careful not to get your hands trapped in the machine. |

| 6. Supervision | Ensure that children are supervised by adults when using the printer to avoid possible personal injury. |

| 7. Emergency | In case of emergency, turn off the power immediately. |